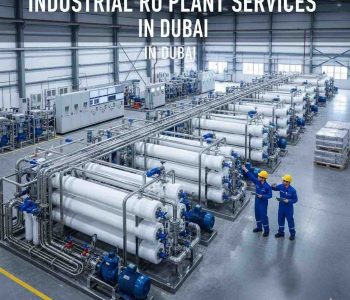

Industrial Reverse Osmosis (RO) plants are vital water treatment systems in Dubai, essential for converting various water sources—including high-salinity seawater, brackish groundwater, and treated wastewater—into high-ppurity water suitable for industrial processes, drinking, and other specific applications. With Dubai’s limited natural freshwater reserves, these large-scale systems are critical for ensuring water security and meeting the demands of its diverse industries.

The Role and Importance of Industrial RO in Dubai

- Desalination: For coastal industries and municipalities, large-scale industrial RO plants are a primary method for desalinating seawater to produce fresh, potable water. This is crucial for Dubai’s rapid urban expansion and tourism industry.

- Water Recycling: To conserve freshwater resources, industrial RO plants are increasingly used for advanced wastewater treatment and reuse in applications like irrigation and cooling towers, aligning with Dubai’s sustainability goals.

- Process Water: Many industries, including pharmaceuticals, food and beverage, and electronics manufacturing, require ultra-pure water to prevent contamination and ensure product quality. Industrial RO systems provide water that meets these stringent standards.

- Boiler Feed Water: Industrial RO plants are used in power generation to produce high-quality boiler feed water, which prevents scaling and corrosion in expensive machinery, thereby enhancing efficiency and extending equipment life.

Key Components of an Industrial RO Plant

An industrial RO system is a complex, multi-stage water treatment facility.

1. Pre-Treatment System

This is the first line of defense, designed to remove suspended solids, large particles, and contaminants that could damage the sensitive RO membranes.

- Multimedia Filters: Remove larger particles, sediment, and turbidity to prevent membrane clogging.

- Activated Carbon Filters: Remove chlorine, organic compounds, and other substances that can degrade the RO membrane and affect water taste and odor.

- Water Softeners (Optional): Used for feed water with high hardness (calcium and magnesium) to prevent scaling on the membranes.

- Chemical Dosing System: Accurately injects chemicals like antiscalants and biocides to protect the membranes from scaling and bacterial growth.

- Cartridge Filters: Serve as a final filtration stage to catch any remaining fine particles before the water enters the high-pressure pump.

2. High-Pressure Pumping Unit

- This unit provides the driving force for the entire RO process. High-pressure pumps force the pre-treated water through the semi-permeable membranes to overcome osmotic pressure and enable the purification process.

3. Reverse Osmosis (RO) Membrane Assembly

- This is the core of the system where the separation occurs. It consists of multiple pressure vessels, each containing several spiral-wound membrane elements.

- Pressure Vessels: Robust casings designed to hold the membrane elements and withstand the high pressures required for filtration.

- Membrane Elements: The actual filtration units that reject dissolved salts, viruses, and other impurities while allowing pure water to pass through.

4. Post-Treatment System

- This final stage treats the purified water (permeate) to meet specific quality requirements before it is stored or used.

- UV Sterilizers: Use ultraviolet light to disinfect the water by destroying any remaining bacteria or viruses.

- Remineralization (Optional): Re-introduces essential minerals into the water, particularly for drinking water applications, to improve taste and health benefits.

- Storage and Distribution: The treated water is stored in tanks and distributed as needed.

Process Flow of an Industrial RO Plant

- Raw Water Intake: Water is drawn from its source (sea, borehole, or municipal supply).

- Pre-Treatment: The water undergoes multi-stage filtration to remove large solids, suspended particles, and chemicals.

- High-Pressure Pumping: The pre-treated water is pressurized to the required operating pressure.

- Reverse Osmosis: The pressurized water is forced through the RO membranes, separating into a clean water stream (permeate) and a concentrated reject stream (brine).

- Post-Treatment: The permeate is disinfected and, if needed, remineralized to achieve the desired quality.

- Storage and Distribution: The final product water is stored and supplied for its intended purpose.

Design Considerations for Dubai

- Feed Water Quality: The design must account for the high salinity of seawater and the potential for contaminants in brackish water, requiring robust pre-treatment and specialized membranes.

- Energy Efficiency: With energy costs being a significant factor, low-energy membranes and energy recovery devices are crucial for optimizing operational costs.

- Environmental Compliance: Strict regulations in Dubai govern the discharge of brine. The design must ensure that concentrate discharge is managed to minimize environmental impact.

- Modularity and Space: Containerized or skid-mounted RO plants are often preferred for their ease of installation, scalability, and smaller footprint.

Suppliers and Providers in Dubai

An ISO 9001-2015 certified company providing a range of RO solutions, from brackish and seawater plants to customized systems.

Specializes in RO systems and provides installation, maintenance, and support for both commercial and industrial applications.

Offers a wide selection of RO systems and provides comprehensive maintenance support throughout the UAE.

- Aquapro: A provider of various industrial RO systems with capacities suitable for high-volume applications in manufacturing, bottled water, and more.

Maintenance and Troubleshooting

Regular maintenance is key to prolonging the lifespan and ensuring the performance of an industrial RO plant.

- Routine Inspections: Daily checks of pressure gauges and flow meters to monitor system health.

- Filter Replacement: Regular replacement of pre-filters and cartridges is essential to prevent membrane clogging.

- Membrane Cleaning: Periodic Clean-in-Place (CIP) is required to remove scaling and fouling from membranes.

- Troubleshooting Common Issues: Issues like low water pressure, reduced permeate flow, or poor water quality can often be resolved by checking for clogged filters, inspecting seals, or addressing low feed pressure.